1. Manual Powder Spraying Equipment Overview and Components

Manual Powder Spraying Equipment is a portable system designed for small-scale or precision coating tasks. Key components include a handheld electrostatic spray gun, powder hopper, air compressor, and grounding cable. These devices rely on operator skill to apply powder evenly, making them ideal for workshops with limited automation needs.

2. Applications of Manual Powder Spraying Equipment

Commonly used in automotive repair (bike frames, car parts), furniture restoration (metal fixtures), and artisanal projects (decorative items), manual systems offer flexibility for low-volume jobs. They are also favored in prototyping and custom coating applications where detailed control is critical.

3. Manual Powder Spraying Equipment Pricing

Prices range from 500∗∗forbasickitsto∗∗5,000 for advanced models with adjustable voltage (30–80 kV) and digital displays. Entry-level guns start at 200,whilecompletesetupswithcuringovenscost1,500–$3,000. Used equipment can reduce costs by 30–50%.

4. Step-by-Step Operation of Manual Spraying Systems

Pre-treat surfaces via sandblasting or degreasing.

Fill the hopper with powder and connect the gun to an air compressor (10–30 psi).

Set electrostatic voltage to 40–70 kV for adhesion.

Spray in steady, overlapping motions 6–12 inches from the surface.

Cure coated items in an oven at 160–200°C for 10–15 minutes.

5. How to Choose the Right Manual Powder Spraying Equipment

Prioritize lightweight, ergonomic designs for extended use. Look for guns with adjustable airflow and voltage. Check compatibility with your compressor’s PSI range. Opt for models with easy-clean nozzles and CE/UL certifications for safety.

6. Safety Precautions for Manual Powder Coating

Work in well-ventilated areas to avoid inhaling powder. Wear NIOSH-approved respirators, gloves, and goggles. Ground the gun and workpiece to prevent electrostatic shocks. Avoid spraying near open flames or sparks.

7. Cost-Benefit Analysis of Manual Systems

Manual equipment reduces upfront costs by 80% compared to automated systems. While slower, they eliminate recurring expenses like robotic programming. Ideal for small businesses, they achieve ROI within 6–12 months for frequent users.

8. FAQs About Manual Powder Spraying Equipment

Q: Can manual guns achieve professional finishes?

A: Yes, with proper technique and surface preparation.

Q: How often should I clean the spray gun?

A: Clean after each use to prevent clogging and ensure performance.

Q: Are manual systems suitable for large parts?

A: Yes, but may require multiple coats and longer curing times.

Q: What powders work best with manual equipment?

A: Epoxy and polyester powders are most common.

Q: How to reduce powder waste manually?

A: Maintain consistent distance and use a powder recovery booth.

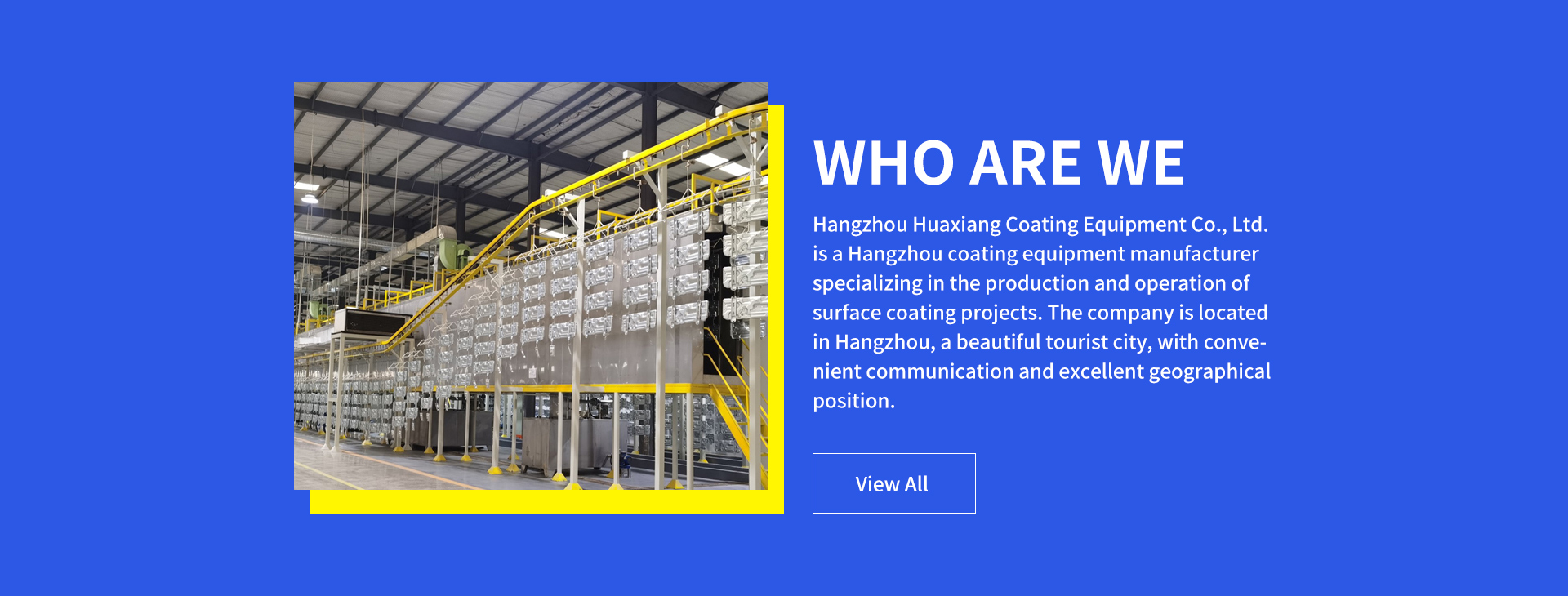

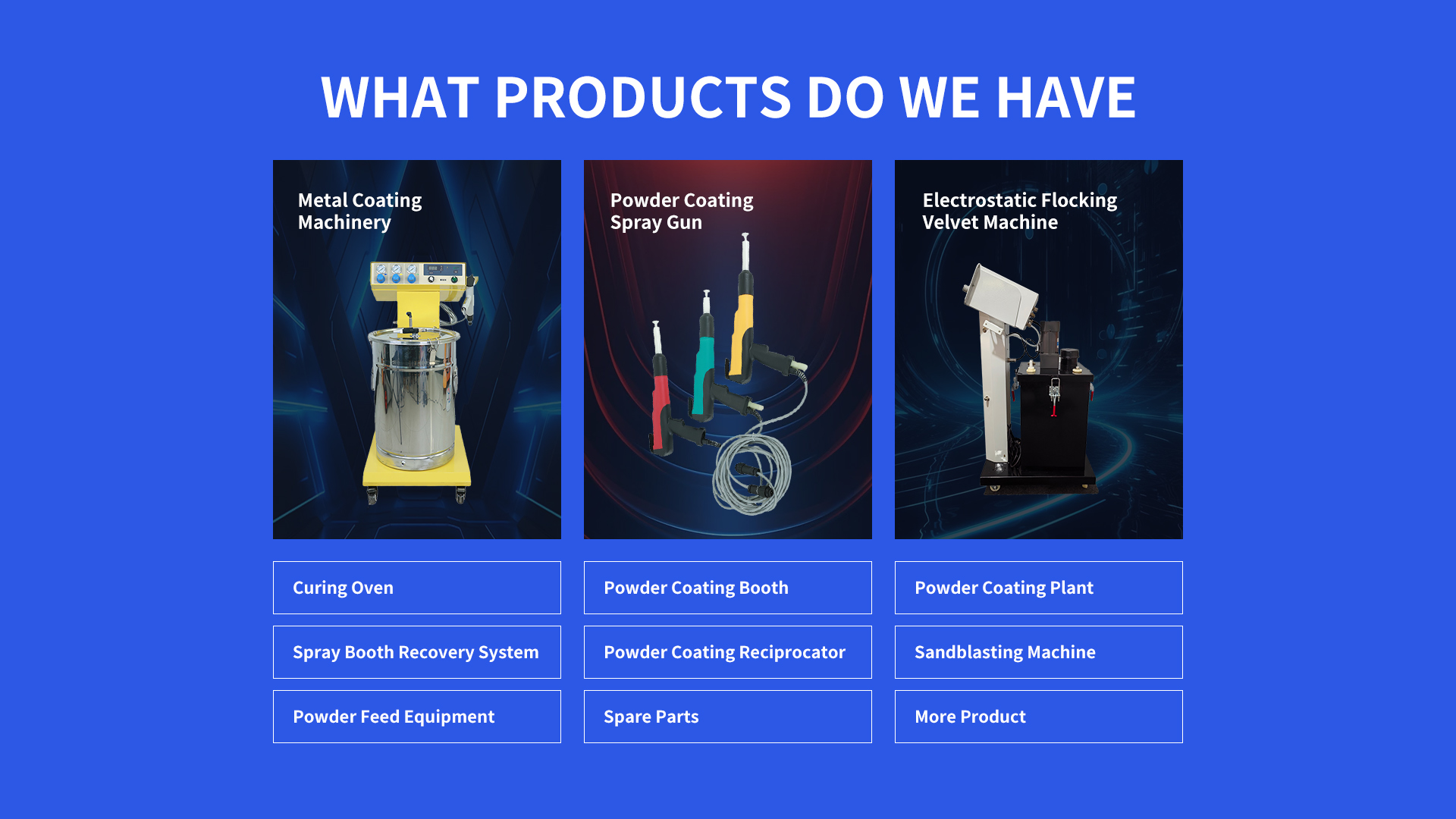

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com