A Powder Coating Booth is a controlled workspace designed to apply and cure powder coatings efficiently while minimizing environmental contamination. These booths feature advanced filtration systems, ventilation controls, and recovery mechanisms to capture overspray, ensuring operator safety and reducing material waste. Ideal for automotive, aerospace, and industrial manufacturing, modern booths are modular, fire-resistant, and customizable in size. They enhance coating quality by maintaining consistent airflow, preventing dust contamination, and supporting rapid curing processes. With energy-efficient designs and compliance with OSHA standards, powder coating booths are essential for achieving durable, high-finish results sustainably.

1. Powder Coating Booth Overview and Components

A Powder Coating Booth comprises a spray chamber, exhaust system, filtration units, and powder recovery modules. The spray chamber, often made from galvanized steel or FRP, houses the coating process. High-efficiency filters (e.g., cartridge or cyclone) capture airborne particles, while exhaust fans maintain negative pressure to contain overspray. Recovery systems recycle unused powder, reducing costs. Additional features include LED lighting for visibility, fire suppression systems, and adjustable airflow vents. Industrial models integrate conveyor systems for automated part handling.

2. Applications of Powder Coating Booths

Powder Coating Booths are vital in automotive refinishing, appliance manufacturing, and architectural metalwork. They coat engine components, bicycle frames, and outdoor furniture with precision. Aerospace industries use large-scale booths for aircraft parts requiring corrosion resistance. Small businesses utilize compact booths for custom signage or DIY projects. Their versatility extends to agricultural machinery, electrical enclosures, and consumer electronics, ensuring uniform finishes across high-volume and niche applications.

3. Design Considerations for Powder Coating Booths

Size and layout must match production volume—overcrowding disrupts airflow. Opt for fire-resistant materials and spark-proof electrical systems to meet safety regulations. Airflow velocity (typically 100–150 ft/min) should balance overspray containment and energy efficiency. Modular designs allow future expansion, while sloped floors facilitate easy cleaning. Integrate HEPA filters for hazardous materials and ensure proper grounding to prevent static discharge. Lighting placement must eliminate shadows without obstructing spray patterns.

4. How to Choose the Right Powder Coating Booth

Assess workspace size and production needs—benchtop booths suit small shops, while walk-in models fit industrial lines. Prioritize filtration efficiency (≥98% for standard powders) and recovery rates to cut material costs. Compare airflow CFM (cubic feet per minute) ratings; 1,500–5,000 CFM suits most applications. Check compliance with EPA and OSHA standards. For limited budgets, pre-owned or modular booths offer cost savings. Test noise levels (ideally below 75 dB) and energy consumption for long-term savings.

5. Powder Coating Booth Q&A

Q: How to maintain a powder coating booth?

A: Clean filters weekly, inspect ductwork for blockages, and vacuum recovered powder daily to ensure airflow efficiency.

Q: Are powder coating booths cost-effective for startups?

A: Yes—recycling systems reduce powder waste by up to 50%, and modular designs scale with business growth.

Q: What safety features are mandatory?

A: Fire-resistant walls, explosion-proof lighting, and emergency shutoff switches are critical for OSHA compliance.

Q: Can booths handle high-volume production?

A: Yes—choose conveyor-integrated booths with automated recovery for continuous operation.

Q: How much space is needed for installation?

A: Allow 3–5 feet around the booth for ventilation and operator movement. Compact models require as little as 50 sq. ft.

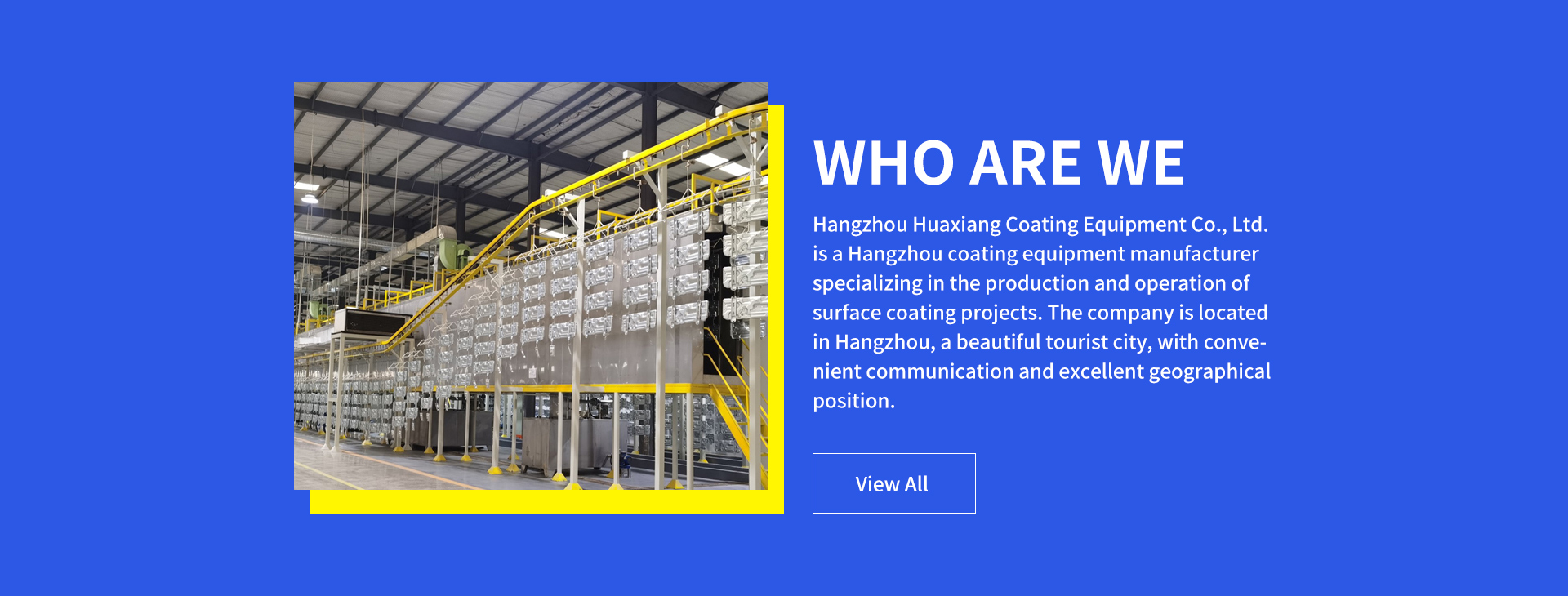

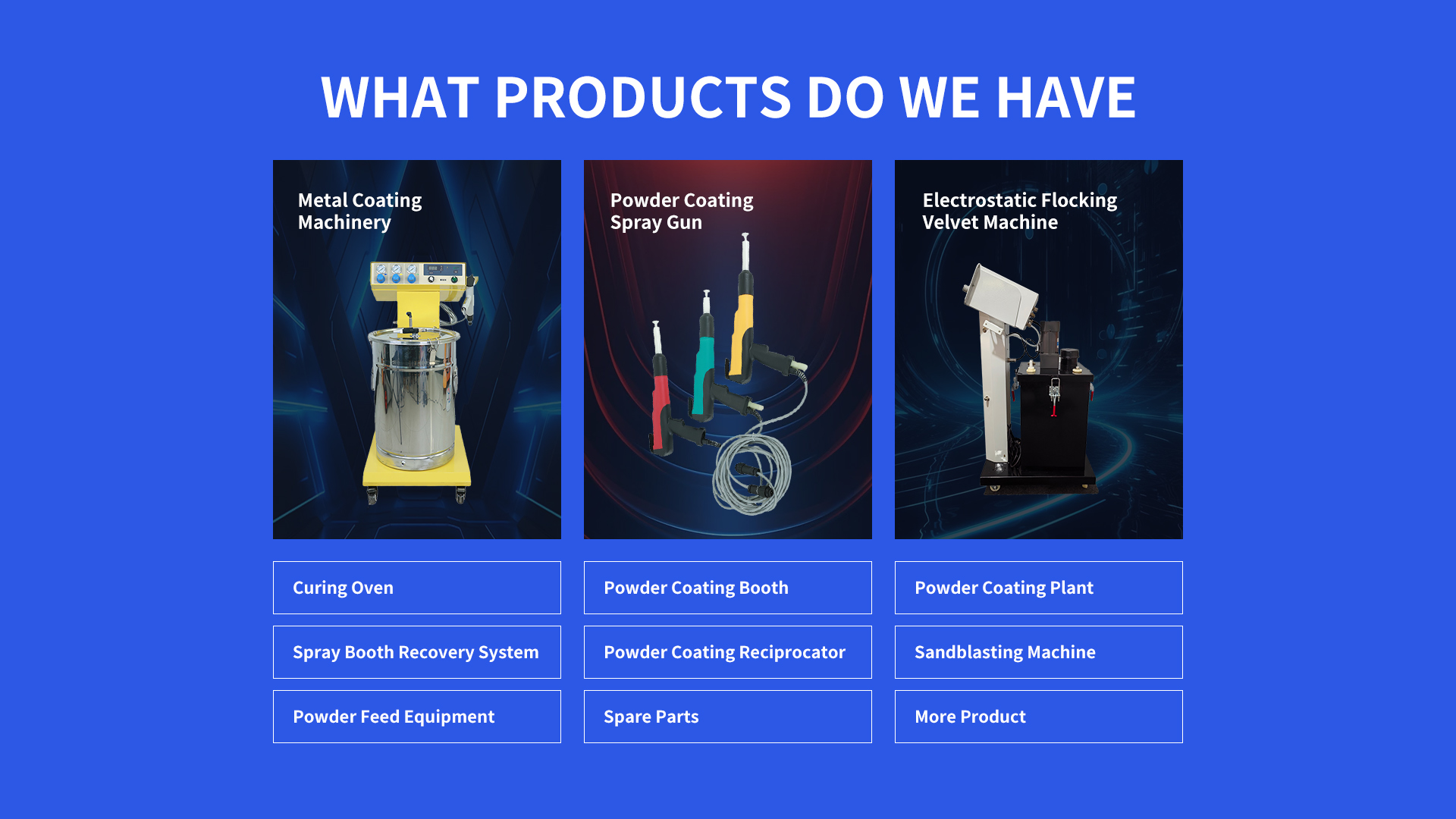

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com