1. Understanding Industrial Powder Coating Machines

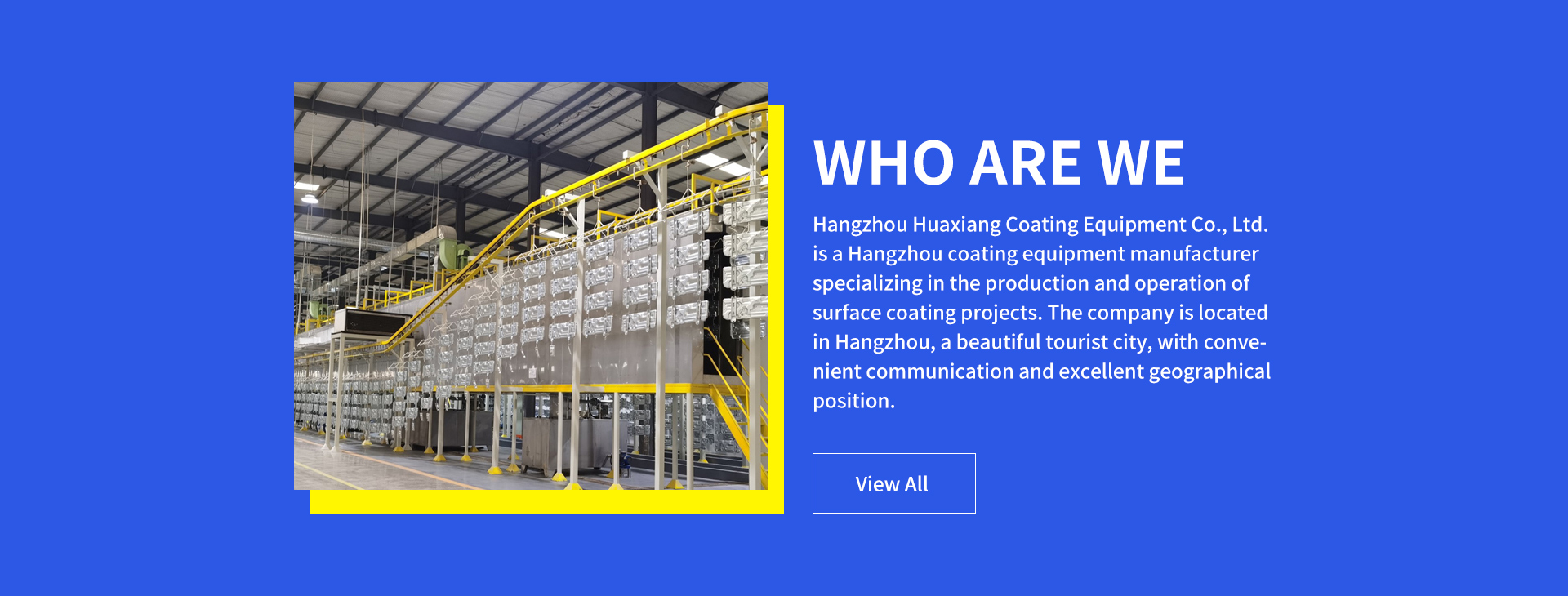

Industrial Powder Coating Machines apply protective dry powder finishes to metal surfaces through electrostatic attraction. These advanced systems create durable coatings that outperform traditional liquid paints in scratch resistance and longevity.

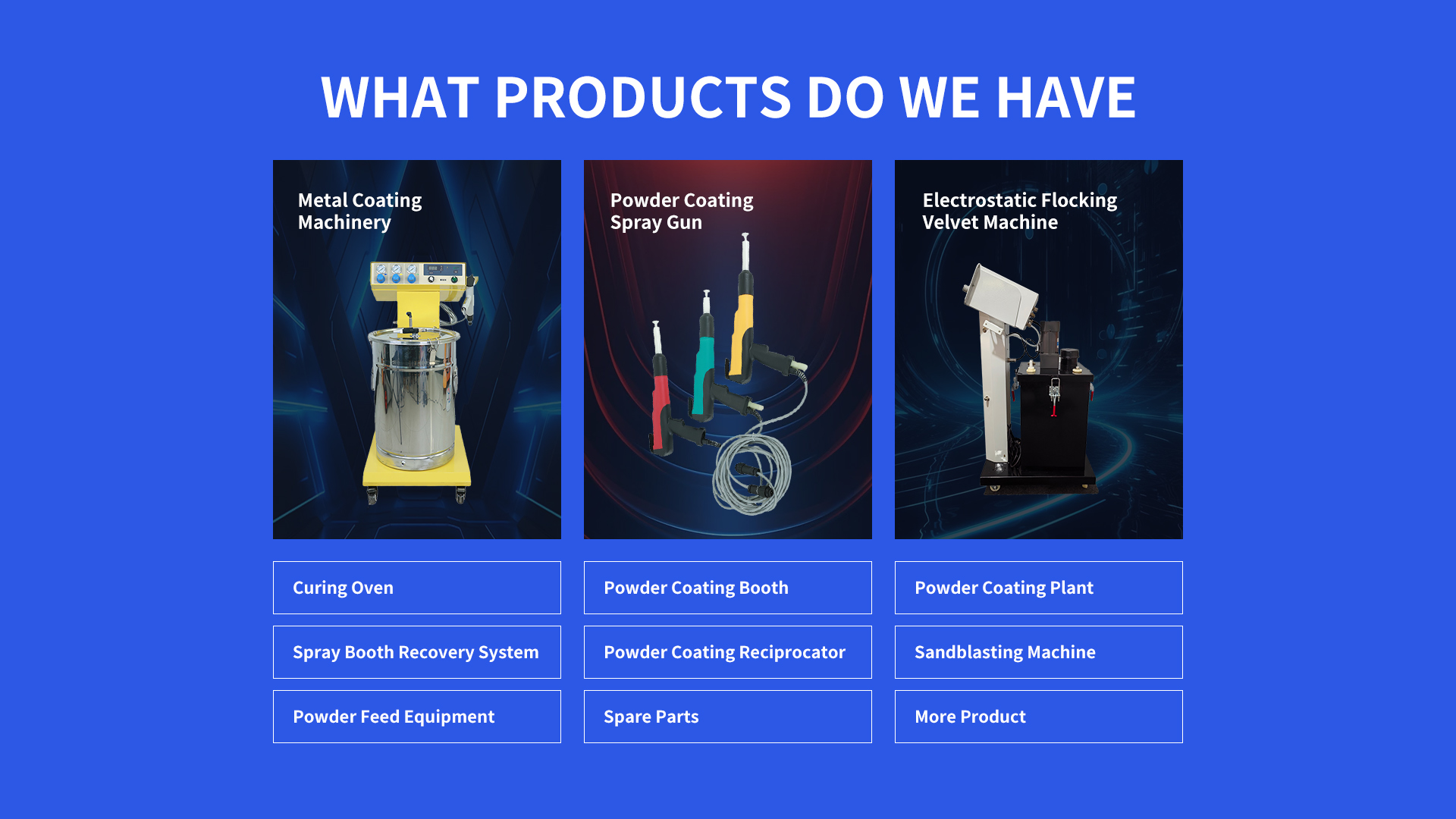

Key components include:

Electrostatic spray guns for precise powder application

Powder recovery systems that recycle up to 98% of overspray

High-efficiency curing ovens with precise temperature control

Automated conveyor systems for production line integration

Modern powder coating systems serve critical functions across multiple sectors:

Automotive manufacturers rely on powder coating machines for:

Construction and architectural firms utilize these machines for:

Investment costs vary significantly based on system capabilities:

Entry-level manual powder coating machines:

Industrial-grade automated powder coating lines:

Follow this professional process for optimal results:

Surface Preparation:

Sandblast to SA 2.5 cleanliness standard

Apply chemical pretreatment

Ensure proper grounding

Coating Application:

Maintain 20-30 cm spray distance

Adjust kV settings based on part geometry

Apply 60-120 micron thickness

Curing Process:

Critical selection factors include:

Production Capacity Needs:

Technical Specifications:

Operational Considerations:

6. Essential Safety Protocols for Powder Coating

Implement these safety measures:

Personal Protection:

Facility Requirements:

Explosion-proof electrical systems

OSHA-compliant ventilation

Proper equipment grounding

7. Advantages of Modern Powder Coating Technology

Superior Performance Benefits:

3-4x more durable than liquid paint

Excellent UV and chemical resistance

Consistent finish quality

Economic Advantages:

8. Powder Coating Machine FAQ

Q: How does powder coating compare to traditional painting?

A: Powder coating provides superior durability, better coverage, and more environmental benefits than liquid paint.

Q: What maintenance do powder coating systems require?

A: Daily filter cleaning, weekly gun maintenance, and monthly oven inspections ensure optimal performance.

Q: Can powder coating be applied to heat-sensitive materials?

A: New low-temperature cure powders allow coating of some heat-sensitive substrates.

Q: What's the typical production speed?

A: Automated systems can coat up to 1,000 parts per hour depending on size and complexity.

Q: How long does powder coating equipment last?

A: Properly maintained systems provide 15-20 years of reliable service.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com